Anode testing services

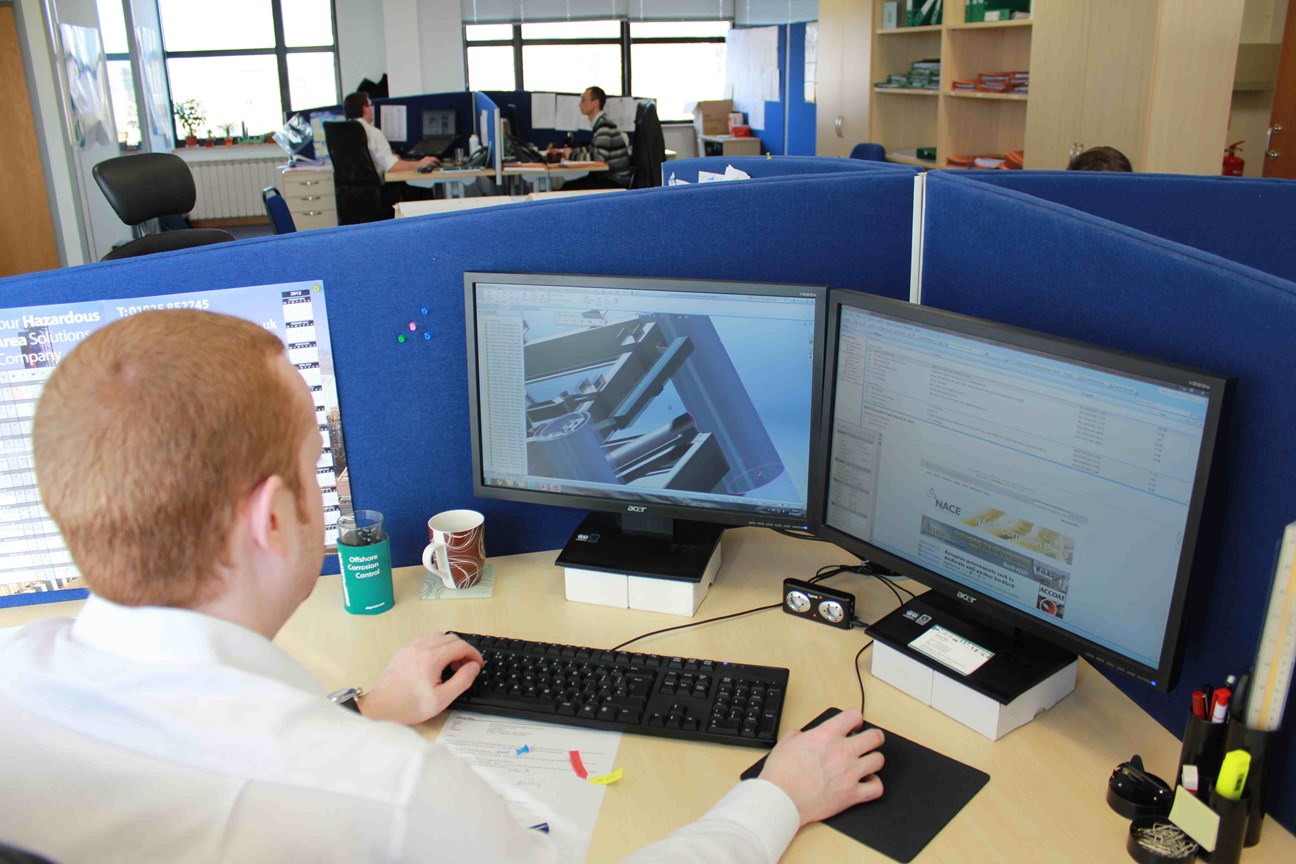

Anode testing services from NACE- certified corrosion experts and engineers

Anode testing services from our team of NACE-certified corrosion experts and engineers.

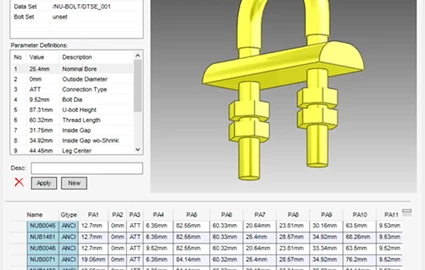

Deepwater now offers an anode electrochemical testing service to ensure the anodes you use are composed of the correct balance of crucial alloys. All testing is conducted by experienced personnel and is overseen by corrosion specialists.

Ambient or cold water testing is available to meet any international test protocol including NACE, DNV, JCS etc. Testing is also available to determine galvanic efficiency and potential. Anode performance under various operational conditions can be simulated in our laboratory.

Deepwater Corrosion Services Inc. is a recognized leader in the field of offshore and marine cathodic protection systems. We are unbiased and competent third-party testers and inspectors. For a second opinion on any corrosion problem, always turn to our team.