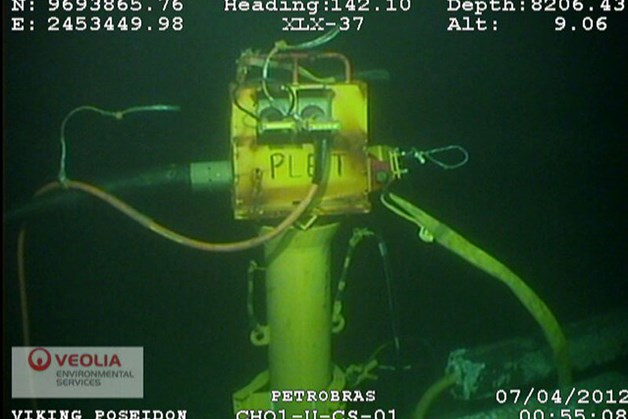

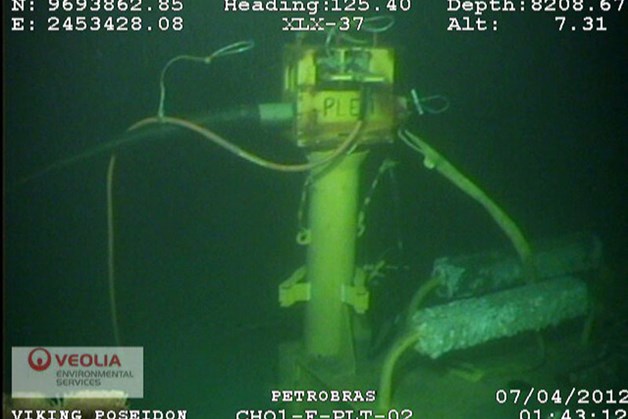

Chinook Field PLET

Deepwater installs a mini-gateway retrofit in the Gulf of Mexico

Deepwater installs a mini-gateway retrofit in the Gulf of Mexico

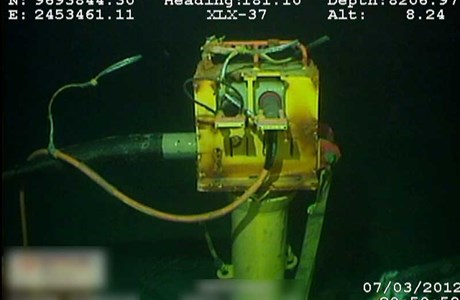

During a July 2012 baseline survey of Gulf of Mexico subsea equipment and pipelines, it was discovered that a crucial component of an umbilical control system was electrically isolated from cathodic protection. Deepwater was asked to design and manufacture a retrofittable electrical jumper system to connect the gateway to an adjacent structure (PLET), which would allow the umbilical component to "borrow" cathodic protection from the PLET's anodes.

Total project time: 14 days

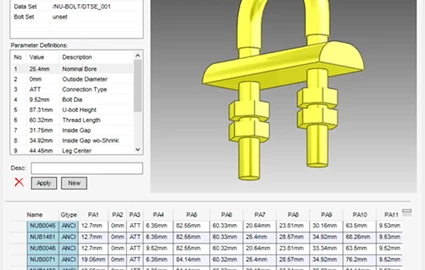

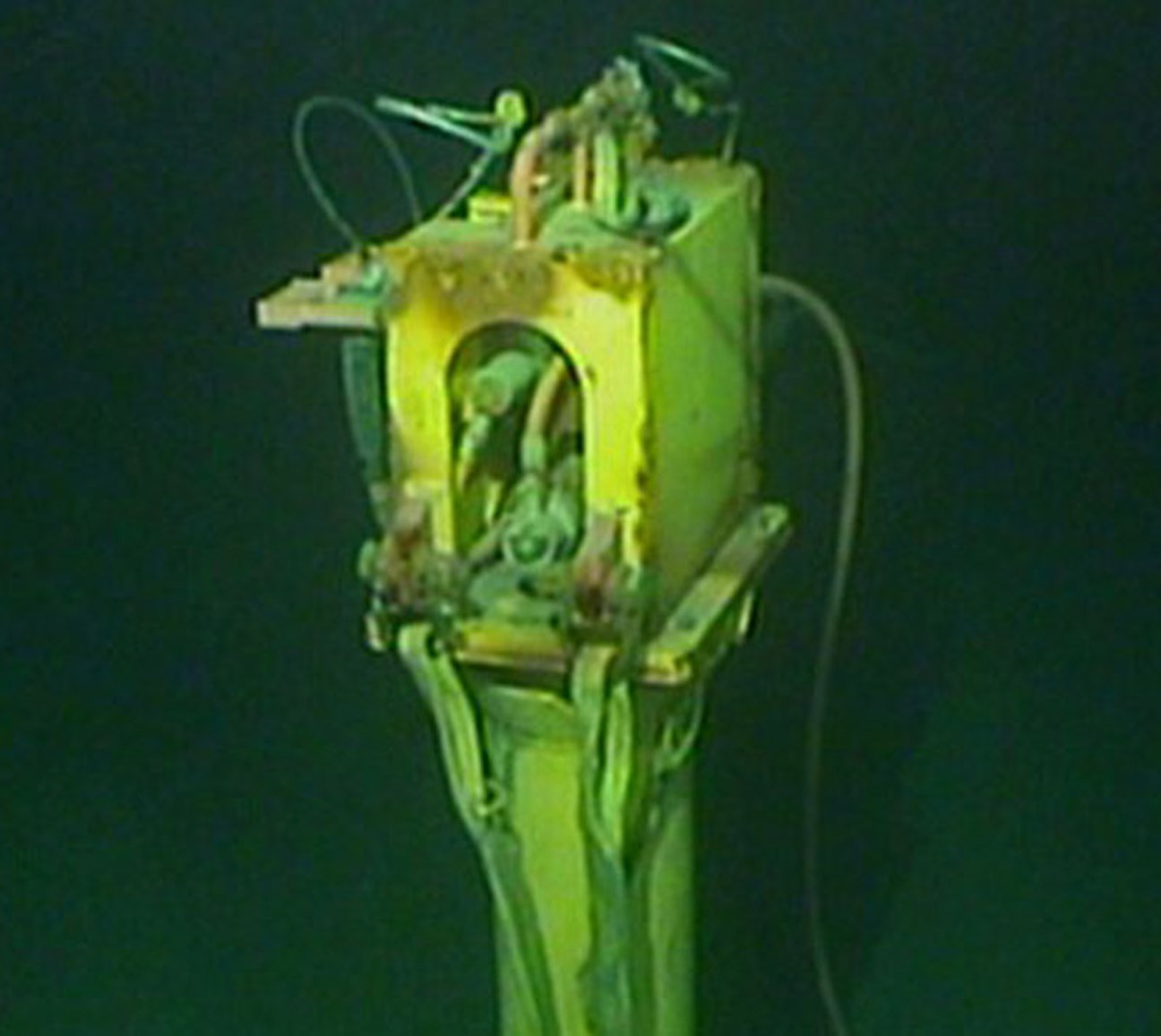

After active corrosion was observed on the mini-gateway, it was discovered the component was receiving no cathodic protection. The mini-gateway plugs into a receptacle on the PLET frame. This component has no sacrificial anodes mounted directly to it. Mixed materials - stainless and carbon steels - in the absence of CP create a very aggressive galvanic coupling. Within a week, Deepwater had proposed a solution in the form of a custom-designed jumper system. This solution was immediately approved by Petrobras, and within one week, Deepwater designed, manufactured and shipped a custom RetroClamp jumper system to site.

The objective was to connect one RetroClamp to the pad-eye of the unprotected umbilical and another RetroClamp to the PLET tubular member below it (see photos). Flexible, high tensile strength jumper cables connected the two clamps. Once the ROV removed a shackle from the pad-eye, the installation of the RetroClamp system took less than half an hour. The umbilical's CP potential shifted from -631mV (unprotected) to -841mV (protected) versus Ag/AgCl reference electrode.