Project experience

30 Years of cathodic protection, inspection and consulting projects around the world

Filter your selection

BARD Offshore 1 OSS retrofit

Remote impressed current cathodic protection system retrofit to replace spent anodes on a German offshore wind farm OSS platform.

Key project stats

- Platform installed 2010

- Premature anode failure

- 25-year design life

Dana Triton FPSO retrofit

Deepwater installs the RetroSAM™ anode system in 2021 to protect the hull of a floating production storage and offloading unit (FPSO) in the North Sea.

Key project stats

- Installation: Topside

- Unit is storm-recoverable

- Remote O&M

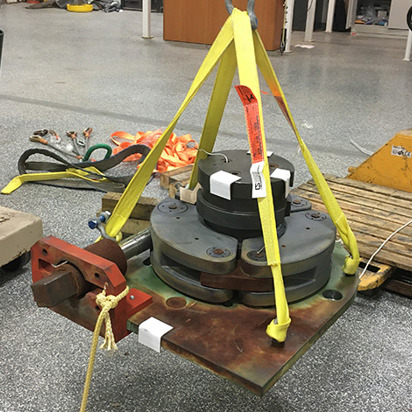

Who Dat retrofit with suspended ICCP anodes

Three sides of the Who Dat platform in the Gulf of Mexico were left unprotected by a failing CP system. Deepwater installed a suspended ICCP anode system as a short-term, low-cost method to temporarily maintain proper CP levels.

Key project stats

- Most existing ICCP anodes had failed

- Suspended anode chosen as fastest, lowest-cost option

- Existing transformer/rectifier used

- Suspended anode is tethered to prevent damage

California wave park survey

In January 2020, Deepwater performed a corrosion survey on the nation's most advanced wave pool.

Key project stats

- CVI/NDT inspection Done

- 500,000 sq. ft. + facility

- 55+ assets Inspected

- ICCP retrofit recommended

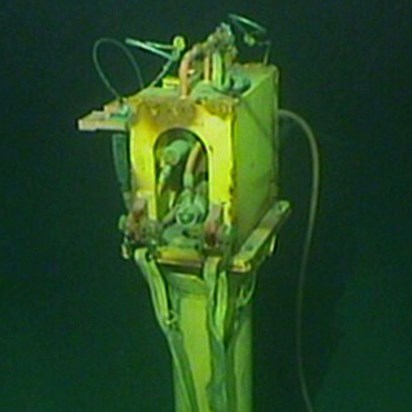

Montara CP test stations

Deepwater provides RetroClamps™ and tie backs to improve electrical continuity between wellheads, piggybacks and PLET, and to have easily accessible CP test stations.

Key project stats

- Wellhead trees and PLET needed electrical continuity

- Piggybacks on flowlines lacked continuity

- Tiebacks were used to ensure electrical continuity

- RetroClamp™ CP test stations were added

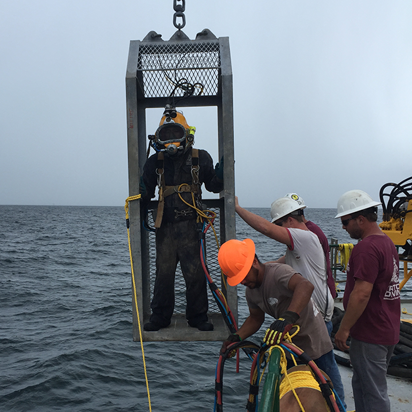

Houston Ship Channel dock

In 2017-18, Deepwater retrofitted the cathodic protection system on 5 docks at the Houston Ship Channel terminal.

Key project stats

- 5 docks protected

- Installation: Divers

- 47 RetroLinks™ installed

- 16 ICCP anodes installed

Offshore wind farm

In 2018-9, Deepwater retrofitted the cathodic protection system on 33 wind turbines in a German offshore wind farm.

Key project stats

- Field: 33 tripod turbines

- Install: < 24 hrs / turbine

Leman Alpha

In 2017, Deepwater retrofitted the cathodic protection system on the structures in the Leman complex.

Key project stats

- Install: 12 hours per buoy

- Depth: 35 M

- 25-year design life

TAQA North Cormorant

The platform was installed with a galvanic anode cathodic protection (CP) system, mounted directly on to the jacket.

Key project stats

- Fixed platforms

- Installation: ROV

- Install time: 18 hrs

Tapis-F & Irong Barat B

RetroPods™ and RetroClamps™ used to replace depleted anodes to extend cathodic protection on two fixed platforms for 20 years.

Key project stats

- Fixed platforms

- Installation: ROV

- Install time: 63 hrs

Tabu, Guntong, Semangkok

RetroSleds™ and RetroClamps™ used to replace depleted anodes discovered during a pipeline survey campaign in Malaysia.

Key project stats

- 3 pipelines

- Installation: ROV

- Install time: 4 days

Dudgeon OWF

In 2016, Deepwater installed remote cathodic protection monitoring on four offshore wind turbine generators

Key project stats

- 4 offshore turbines

- 32 km offshore

Liverpool Bay OSI

Deepwater installs the RetroSAM™ anode system to protect the hull of the offshore storage installation (OSI) at Liverpool Bay.

Key project stats

- Installation: Topside

- Offshore time: 4 days

- Unit is storm-recoverable

- 10 year life extension

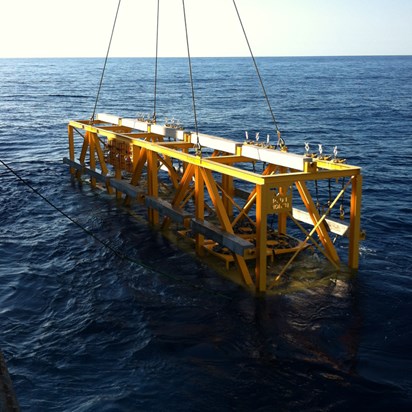

Olympus Field PBGs

Deepwater installs self-monitored anode sleds in the Gulf of Mexico to protect 24 new PGBs at 3,000 ft for 45 years.

Key project stats

- Installation: ROV

- Install time: 30 hours

- Battery-free monitoring

- 45-year design life

Ewing Bank 305-A

Deepwater added 20 years of anode life to EW-305 with two RetroBuoy™ impressed current cathodic protection sleds.

Key project stats

- Water depth: 300 ft

- 20 year life extension

- 800 Amps of CP current

ERWB Jackets

Deepwater installs RetroPods™ and V-Strings™ in the Gulf of Thailand to extend the life of two bridge-connected jackets in 200 ft of water.

Key project stats

- Bridge-connected jackets

- Water depth: 200 ft

- Install time: 60 hours

- Seabed anodes only

LAF-1 & 2 Platforms

Deepwater installs three impressed current cathodic protection retrofit anode sleds on 2 platforms in the Gulf of Guinea, extending the life by 20 years.

Key project stats

- Installation: ROV

- Impressed current anodes

Eugene Island 295-A

RetroLinks™ installed on Nexen platform in the Gulf of Mexico to restore cathodic protection.

Key project stats

- Installation: Divers

- Install time: 60 hours

- Depth: 220 ft

8 inch pipeline

Deepwater was contracted by Chevron to provide cathodic protection (CP) retrofit materials for their 8” wet oil pipeline running from their fixed jacked to shore.

Key project stats

- Installation: Divers

- Offshore time: 30 hours

- Length: 4.5 km

- As left: -0.998V vs Ag/AgCl

Offshore drill stack

Cathodic protection levels monitored and corrected on a drill stack in Australia, with remediation to coating and sacrificial anodes.

Key project stats

- Recap Datalogger

- CP & Coating Remediation

Chinook Field PLET

Under pressure, Deepwater designed and installed a mini-gateway retrofit anode system in the Chinook field on a PLET.

Key project stats

- Continuity jumper

- Borrowed CP from PLET

- Custom design

- 2 week turnaround

24 inch methanol pipeline

Concrete mattresses with integral anodes (RetroMat™) used to retrofit new cathodic protection for a pipeline in Equatorial Guinea.

Key project stats

- Local assembly

- Offshore time: 3 days

- Length: 2 km

- As left: -1.025V vs Ag/AgC

Black Bay platforms

In 2012, Deepwater retrofit new anode strings for 69 structures in Black Bay, extending the cathodic protection life of the field.

Key project stats

- 115 anode strings

- 22 continuity jumpers

- Structures: 69

- Offshore time: 22 days

South Pass 62-C

Two RetroBuoy™ systems replace spent anodes on a 330 ft platform in South Pass, Gulf of Mexico adding 20 years of life.

Key project stats

- Install time: 30 hours

- Depth: 330 ft

- 20 YEAR DESIGN LIFE

Forties Field platforms

Deepwater successfully designed, deployed and commissioned 9 (nine) RetroBuoy™ systems to 4 (four) fixed platforms located in the North Sea.

Key project stats

- 4 fixed platforms

- 9 x 450 Amp sleds

- Install: 12 hours each

- 20-year design life

Lufeng 13-2

Impressed-current cathodic protection system retrofit to replace spent anodes on a South China Sea platform.

Key project stats

- Platform installed 2005

- Premature anode failure

- Depth: 430 ft

- Supplemental ICCP anodes

Ras Gharib platform

New anodes retrofitted for a fixed platform in the Egyptian Red Sea boost the cathodic protection system for 20 more years.

Key project stats

- Install: Divers

- Install time: 24 hours

- Depth: 14 m

- As left: (-)1.050V vs Ag/AgCl

Arklow Bank

In June 2005, Deepwater supplied and supervised the installation of seven (7) impressed current anodes on wind turbine monopiles in the Irish Sea.

Key project stats

- 7 x wind turbines

- Water depth: 10 m

- Offshore time: 11 days

Alba Field

Pipeline anode retrofit of an offshore process pipeline in Equatorial Guinea's Alba Field with low cathodic protection potentials.

Key project stats

- Installation: ROV

- Depth: 200 ft

- Sacrificial anode sled

Galveston Island Historic Pleasure Pier retrofit

Deepwater supplied the RetroLink™ system accompanied by RetroClamp™ subsea clamps to provide CP to the forty-seven steel columns supporting the pier.

Key project stats

- RetroLink™ anode strings installed

- Anode strings attached with RetroClamps™

- CP levels verified using Polatrak ®CP Gun™

Bahamas loading dock

RetroLink™ anode string system was used to replace the damaged cathodic protection system for loading dock in the Bahamas.

Key project stats

- Sacrificial anodes

- Diverless install

Cook Inlet Pier

Deepwater develops Raparound™ pile anodes for harsh conditions in the Cook Inlet, Alaska, where all others had failed.

Key project stats

- 1,800 AMPS of CP

- Freeze / thaw resistant

Duncan Wharf

A cathodic protection retrofit for the Duncan Wharf, an aluminum loading berth in Port Alfred with ICCP anodes.

Key project stats

- Semi-Arctic temperatures

- 3,700 AMPS of CP

Forties field flowlines

Anode retrofit for the in-field flowlines on the Forties field in the North Sea

Key project stats

- Install time: 60 hours

- Depth: 106 m

Kitchen Lights

Impressed current anode system designed for a new platform in Alaska

Key project stats

- New fixed jacket

- Cook Inlet, Alaska

- Impressed current

Arnold / Oyster fields

New cathodic protection anodes installed on two deep-water fields in just 73 hours, including well trees, flow line manifolds, umbilical termination units, and flow lines.

Key project stats

- Installation: ROV

- Install time: 72 hours

- Depth: 775 ft / 1,750 ft

GOM structures

Deepwater replaces aluminum cathodic protection anodes on 5 platforms in the Gulf of Mexico in 14 days with the RetroPod™ system.

Key project stats

- 5 fixed jackets

- Install time: 14 days

- 210' four point boat

Shenzi subsea tree

The first SunStation™ cathodic protection monitoring system, installed on a Shenzi subsea Christmas tree, was interrogated by ROV.

Key project stats

- Water depth: 4,300 ft

- 25-year monitoring system

- No batteries required

Garden Banks 191-A Anode retrofit

Deepwater retrofits cathodic protection on a fixed platform in 720 ft. water in less than 2 days with the RetroBuoy™ impressed current system.

Key project stats

- Water depth: 720 ft

- Installation: ROV

- Install time: 2 days

Tubular Bells

Sacrificial anode retrofit for two pipelines located in the Mississippi Canyon area of the Gulf of Mexico.

Key project stats

- Water depth: 4,500 ft

- Installation: ROV

Joliet TLP

RetroPod™ anode sleds and RetroClamps™ retrofit cathodic protection anodes on a tension leg well platform in Green Canyon, Gulf of Mexico.

Key project stats

- Water depth: 1,760 ft

- 19 x RetroPods™

6 Bay Marchand platforms

61 RetroLink™ anode strings provide new cathodic protection for six shallow-water structures in the Gulf of Mexico.

Key project stats

- 6 structures

- 61 anode strings

- 5 year life extension

PanYu 30-1

RetroBuoy™ impressed current anode sleds installed to retrofit cathodic protection on an 8 leg fixed platform in the South China Sea.

Key project stats

- Water depth: 200 m

- Fixed monitoring

Frying Pan Tower

Deepwater designs an anode string retrofit for an offshore bed and breakfast on a former lighthouse platform of North Carolina.

Key project stats

- Civilian owned

- 12 RetroLinks™

Ship Shoal structures

64 RetroLink™ anode strings used to protect wellhead platforms, gas lift manifolds and production platforms, including pipeline risers in the Gulf of Mexico.

Key project stats

- 64 RetroLinks™

- 25 structures

Zafiro Producer

Deepwater installs a RetroBuoy™ ICCP anode sled retrofit system on ExxonMobil's Zafiro Producer FPSO in Equatorial Guinea.

Key project stats

- Water depth: 590 ft

- Dynamic cable

- 800 Amps CP

Green Canyon

Deepwater supplied seven RetroPod™ anode sleds for Neptune 6 and Shenzi 8 platforms in the Gulf of Mexico

Key project stats

- Water depth: 4,400 ft

- Install time: 3 days

Brent pipeline

Deepwater retrofits major North Sea pipeline using RetroMat™ and RetroClamp™ to provide pipeline cathodic protection.

Key project stats

- 12 km pipeline

- Conctrete weight coat

- 15 year life extension

Hydrogen embrittlement study

In 2020, Deepwater Corrosion Services Inc. was contracted to conduct laboratory testing including potential monitoring of a clamp connector subject to cathodic protection (CP).

Key project stats

- Study focused on clamp connector

- Possible gasket embrittlement from CP

- Internal sections of clamp monitored for CP

- Polarization of gasket could generate hydrogen

Pipeline Excavation Tool (PET™) installs RetroClamp™

Pipeline Excavation Tool (PET™) is used to excavate a shallow buried underwater pipeline in south Louisiana to install a RetroClamp™ for attaching leads to a CP test station.

Key project stats

- Entire operation done from topside - no divers

- Took two hours to excavate and install RetroClamp™

- Whole operation including setup and demob took one day

Enterprise dock anodes

Deepwater oversaw installation of galvanic anodes on the Beaumont Marine East and Beaumont Marine West dock facilities near the Gulf of Mexico, including installation of continuity cables to discontinuous sections.

Key project stats

- Sections of dock, dolphins and piles had insufficient CP

- Anodes added to supplement existing land-side ICCP

- Continuity cables added to discontinuous sections

LINCS wind farm monitoring

Deepwater installed corrosion monitoring systems on a representative sample of wind turbine generator monopiles in the LINCS wind farm.

Key project stats

- Wind monopiles without internal coating or CP

- Long-term monitoring on sampling of structures

- Corrosion coupons measure wall loss over time

- Electrical resistance system logs data

Gunfleet Sands wind farm anodes

Deepwater extended the lives of 38 monopiles in the Gunfleet Sands wind farm and another monopile in the Lincs wind farm. Anode monitoring systems were installed in six of the Gunfleet Sands structures, as well as the Lincs monopile.

Key project stats

- 38 monopiles retrofitted in Gunfleet Sands

- Monitoring added to 6 Gunfleet Sands monopiles

- Monopile in Lincs gets CP retrofit and monitoring

Sheringham Shoal anode strings

It was discovered that the original sacrificial cathodic protection system wasn't protecting external sections of the pile to the seabed. Deepwater installed RetroLink™ anode strings and a monitoring system to test the efficacy of the retrofit.

Key project stats

- Inadequate CP on external sections of pile

- Retrofit couldn't use divers or welding

- RetroLinks™ attached to custom clamps

- Current monitoring and reference electrodes added

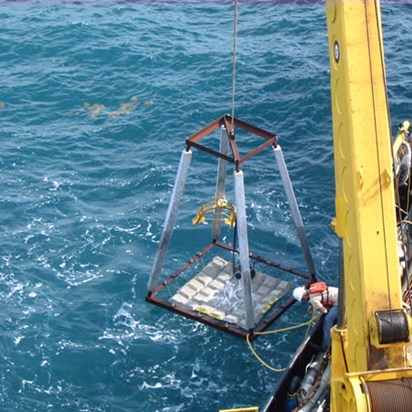

Cathodic protection sleds

Large, heavy-duty SACP anode sleds were constructed for the U.S. government for use in high water currents.

Key project stats

- Heavy duty, lower profile sleds

- For high water current environments

- High-strength piping

- 20-year design life

Case study: Sendje Ceiba FPSO outfitted with RetroBuoy™ ICCP sled

Deepwater installed a RetroBuoy™ ICCP anode sled for a 20-year life extension of an FPSO off the coast of Equatorial Guinea.

Key project stats

- Up to 500 amps for 20 years

- Initial current required: 190 amps

- Final current required: 404 amps

Neptune Spar

In September 2009, Deepwater retrofitted the cathodic protection system on the hull of the Neptune SPAR.

Key project stats

- INSTALL TIME: 72 HOURS

- DEPTH: 1,930 FT

- 15 YEAR DESIGN LIFE

Port of Alaska dock

Deepwater installed 8 Raparound™ pile-mounted anodes on a Cook Inlet dock at the Port of Alaska.

Key project stats

- 8 Raparound™ anodes used

- Divers secured anodes and routed cables

RetroLink™ anode strings installed

Deepwater installed six anode strings on Apache’s EC-2-C 4-pile structure in the Gulf of Mexico.

Key project stats

- Six RetroLink™ anode strings installed

- Depth: 30 feet of water

- Located in Gulf of Mexico

- Total time - including travel - 6 hours

RetroPods™ installed on wellheads and SUTA

Deepwater Corrosion Services was contracted to oversee the installation of three RetroPod™ sacrificial anode systems in the Dolphin Deep oilfield located off the coast of Trinidad in 200 meters of water.

Key project stats

- RetroPod™ anode sleds installed

- RetroClamps™ provide electrical connection

CP jumper system installed on pipeline

The Cathodic Protection jumper system provides a CP bridge across the insulation joint installed on the 12” Cobia pipeline extension in the MP-290 field near the mouth of the Mississippi River.

Key project stats

- Two 12” RetroClamps™ were installed

- Pair of 4/0 cables provide continuity

- ROV installation

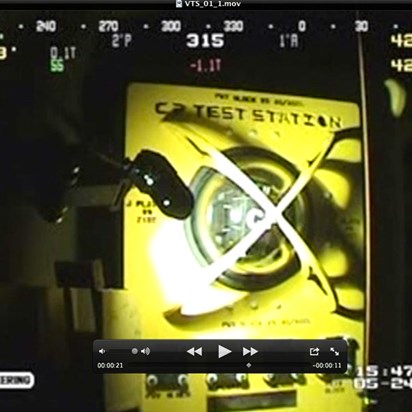

ReCap™ data logger installed on BOP stack

Deepwater was contracted by Atwood Oceanics to install a ReCap™ data logger on one of their BOP stacks to log cathodic protection data during subsea operations. The ReCap™ system comprises a high impedance data logger, two V-String™ zinc reference electrodes and two grounding clamps.

Key project stats

- System includes high - impedance data logger

- Two V-String™ zinc reference electrodes used

- Data recorded every 15 minutes for four years

- Non-stop data logging of two independent channels

Four platforms retrofit near Trinidad

The Galeota A, B, C and D platforms received sacrificial anode retrofits for a 20-year life extension.

Key project stats

- 59 anode sleds were required

- 3 Dual-anode clamp-ons were used

- Smaller booster anodes added to top of sleds

- Systems were connected via RetroClamps™

RetroLinks™ installed on multiple assets

Deepwater provided CP systems for oil and gas assets such as platforms, wellheads and pipeline risers, all spread across various fields.

Key project stats

- A total of five RetroLinks™ installed

- Platforms, wellheads and pipeline risers

- Assets spread over various fields

RetroLinks™ installed on Boardwalk Pipeline

Deepwater was contracted by Boardwalk Pipeline to provide cathodic protection (CP) retrofit materials and installation supervision for their 12” pipeline after finding low CP readings in 2 locations.

Key project stats

- 490 feet of RetroLinks™ installed

- RetroClamps™ attach anodes to pipeline

- RetroReader™ used to confirm connection

Anode sled installed on fixed-jacket platform

Deepwater Corrosion Services was contracted by EMAS to supply and oversee the installation of one anode sled on the fixed jacket platform Aripo located in Trinidad. The purpose of this anode sled was to replace anode material previously removed from the platform due to construction projects.

Key project stats

- Anode sled was attached via RetroClamp™

- Saturation divers used to place sled

Anodes installed in chemical plant storage tank

Deepwater Corrosion Services provided local cathodic protection (CP) using 12 weld-on zinc based anodes for a tank at a chemical plant in DeRidder, Louisiana. Additionally, a potential monitoring panel using zinc reference electrodes was installed on the outside of the tank.

Key project stats

- 12 weld-on zinc based anodes installed

- Potential monitoring panel using zinc reference electrodes was installed

Four RetroSleds™ installed on two pipelines

Deepwater Corrosion Services was contracted by Stone Energy to supply and oversee the installation of four RetroSled™ anode sleds on to two subsea pipelines in the Gulf of Mexico.

Key project stats

- Installed from jack-up boat

- Divers helped place the sleds

- In Gulf of Mexico, south of Louisiana

RetroLinks™ installed on Chevron East platform

Deepwater Corrosion Services was contracted by Chevron East to restore adequate cathodic protection on a caisson structure in the Gulf of Mexico by installing 23 RetroLink™ anode strings.

Key project stats

- RetroLinks™ were attached to 23 horizontal stand-offs

- Caisson structure in 48 feet of seawater

- Two Vamp Clamps™ used for electrical continuity

- 1.5 hours average installation time per anode string

RetroPods™ installed on ExxonMobil platforms in South China Sea

Deepwater Australasia Pty Ltd (DCA) was contracted by Wasco to provide installation support for the cathodic protection life extension of ExxonMobil’s assets Guntong-F (GuF) Platform and Irong Barat-C (IbC), which are both located in the South China Sea.

Key project stats

- Two platforms retrofit

- 36 RetroPods™ total installed on two platforms

- Assets in 63 meters of seawater

Retrolinks™ installed on three platforms

The platforms were cathodically protected only by the sacrificial anodes installed at construction about 48 years earlier. Deepwater supervised the installation of 20 RetroLinks™ on each of the Arenque A, B and C platforms.

Key project stats

- 20 Retrolinks™ used per structure

- Retrolinks™ were 200 feet in length

- Protected for at least 5 years

RetroSled™ installed on subsea pipeline

Deepwater Corrosion Services was contracted to provide a RetroSled™ anode sled and a RetroClamp™ to provide CP for a 6” subsea pipeline.

Key project stats

- Pipeline near Renaissance MP 76 platform

- RetroSled™ used to provide CP

- RetroClamp™ provides electrical connection

- Located in the Gulf of Mexico

Buffalo Bayou sheet pile survey

Deepwater Corrosion Services was contracted to investigate the condition of steel sheet pile walls at two sites along Buffalo and White Oak bayous at the northern end of Houston’s downtown.

Key project stats

- Survey of submerged steel sheet piles

- Identify multiple discontinuities along piles

- 6 of 7 TRs were functioning

- Sampled mud and water for resistivity

160 km pipeline, platform, flare tower retrofit

Deepwater Australasia Pty Ltd was contracted by EMAS Energy to provide installation support for the cathodic protection life extension of PTT’s assets in the Gulf of Thailand: ERP Platform, ERP Flare Tower and the RC210 24” pipeline from ERP to Khanom Shore Base.

Key project stats

- 81 RetroSleds™ and 162 RetroClamps™

- 13 Test stations installed

- RetroMat-CP Test Station™ used on buried pipeline

CP monitoring installed on marine fueling dock

Deepwater Do Brasil Engenharia Ltda installed a CP monitoring system on the Açu Maritime Fuel Terminal - TECMA on December 27, 2020. The dock is used for marine fueling and has two berths: Berth 1, which measures 185m X 32m, and Berth 2, which measures 110m X 21m.

Key project stats

- 8 V-String™ reference electrodes and monitoring panel

- Berth 1: 185m X 32m

- Berth 2: 110m X 21m

Monitoring system for Australian pipeline

Deepwater was contracted in 2018 to supply a SunStation™ system for monitoring the potential of a pipeline using a V-String™ reference electrode and to monitor the output current of an MA-1™ monitored anode on the Spool Connection Assembly (SCA).

Key project stats

- SunStation™ will monitor pipeline CP

- V-String™ reference electrode attached to SunStation™

- MA-1™ will monitor Spool Connection Assembly

RetroLinks™ installed on smaller Gulf of Mexico structure

Deepwater installs RetroLinks™ on smaller Gulf of Mexico structure.

Key project stats

- RetroLink™ anode strings installed

- RetroLinks attached to stand-offs welded to structure

- Smaller structure in Gulf of Mexico

- Water depth: 25 feet

RetroPods™ installed on FPU subsea equipment

Deepwater was contracted to supervise the installation of a cathodic protection (CP) anode retrofit system and perform continuity checks on RetroPods™ and Web-RetroClamps™ for six subsea trees and the clump-weights (gravity base) of an offloading buoy and mid-depth buoys (MDB) on a floating production unit.

Key project stats

- 12 RetroPods™ and 18 Web-RetroClamps™ installed

- 10-year life extension

- 115 meter water depth

Arabian Gulf pipeline CP retrofit

25 RetroClamps™ were utilized to electrically connect retrofit anode sleds on an 8-inch pipeline.

Key project stats

- 25 RetroClamps™ deployed

- 8-inch pipeline from wellhead platform

- Used to electrically connect anode sleds

64 RetroLinks™ installed on pipelines

64 RetroLinks™ were installed on three Gulf of Mexico pipelines using 26 RetroClamps™ to electrically connect them.

Key project stats

- 64 RetroLinks™ used

- 26 RetroClamps™ used to attach links

- Anode strings laid on seabed

Deepwater installs RetroSleds™ to protect two pipelines

Deepwater supplied three RetroSleds™ and six RetroClamps™ for the cathodic retrofit of two offshore pipelines in the Gulf of Mexico.

Key project stats

- 2 RetroSleds™ and 4 RetroClamps™ on 8" pipeline

- 1 RetroSled™ and 2 RetroClamps™ on 12" pipeline

- Pipelines at 210' and 220' depth

PET™ pipeline excavation and clamp installation

Deepwater was contracted to use the Pipeline Excavation Tool to place two large RetroClamps™ on two shallow-water pipelines buried in mud.

Key project stats

- 48" and 30" pipelines under 4' to 6' of mud

- PET™ used to excavate pipes

- Two RetroClamps™ installed

- Excavation time: 2 hours

RetroLinks™ installed on small structure

Deepwater installed 14 RetroLinks™ on a small Gulf of Mexico structure.

Key project stats

- 14 RetroLinks™ installed

- 66" lengths

- Gulf of Mexico

20 RetroLinks™ installed in Gulf of Mexico

Deepwater was contracted to provide 20 RetroLink™ anode strings to protect a four-leg, three-riser platform sitting in 148 feet of water in the Gulf of Mexico.

Key project stats

- 20 RetroLinks™ installed

- 150-foot RetroLink™ length

- Water depth: 148 feet