Corrosion control for energy

Search the Technical Corrosion Archives

Recent projects

SYU platforms anode retrofit

In what was certainly the largest-ever single cathodic protection retrofit, Deepwater Corrosion Services deployed 21,000 Amps of CP using modified RetroBuoy™ sleds to re-establish cathodic protection to three of the deepest offshore platforms in the world.

Triton FPSO hull retrofit

Deepwater engineers replaced failing hull anodes on the Triton FPSO for an additional 15 years of life. Using the RetroSAM™ suspended anode module – the only proven anode retrofit technology for failing hull CP systems – no subsea intervention was required.

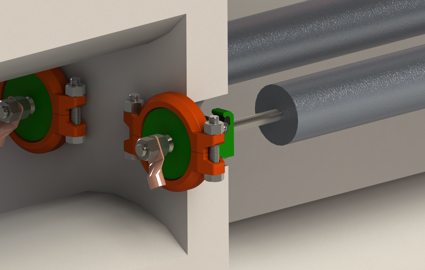

GoM platform retrofit

When the original CP system depleted, CP potentials began to drop. With the downward trend picked up on the annual survey and a planned life extension, the operator chose Deepwater's RetroLink™ anode system, which requires no subsea intervention.

Rapid pipeline excavator (PET)

Deepwater's PET™ (Pipeline Excavation Tool) made short work of excavating two locations on large-diameter pipelines buried in the swamps. Eliminating the need for divers or costly traditional excavations, the PET™ is deployed quickly from a barge or roadside.

Fixed Monitoring Brazil Dock

Deepwater Do Brasil Serviços de Corrosão retrofit the ICCP system and installed a CP monitoring system on the Porto do Açu Maritime Fuel Terminal (TECMA). Annual inspection of the data readings has reduced planned maintenance and dive costs.