Arnold / Oyster fields

Anode retrofit for two deep-water GOM subsea field developments

Deepwater RetroClamp™ was designed for rapid installation by ROV on pipelines.

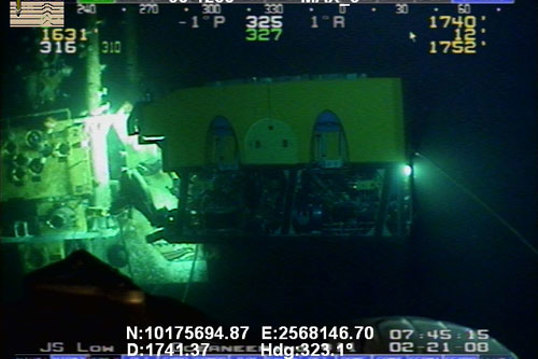

Deepwater Corrosion Services performed anode retrofits on Marathon's "Arnold" and "Oyster" fields in the Gulf of Mexico. These two subsea development systems, located in water depths ranging from 775 to 1,750 feet, were retrofitted in just over 73 hours. Assets to be protected included:

• 4 flowlines, ranging in length from 3 to 9 miles each

• 4 well trees

• 2 flowline manifolds

• 2 umbilical termination units

The cathodic protection (CP) system consisted of:

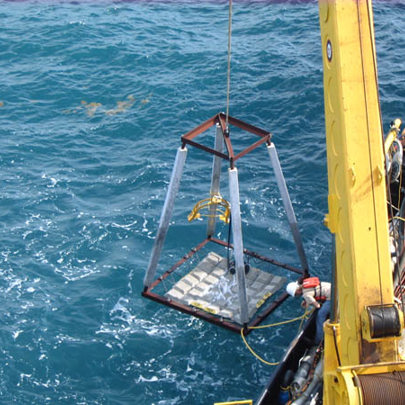

• 19 RetroPods™ (Aluminum sacrificial anode sleds)

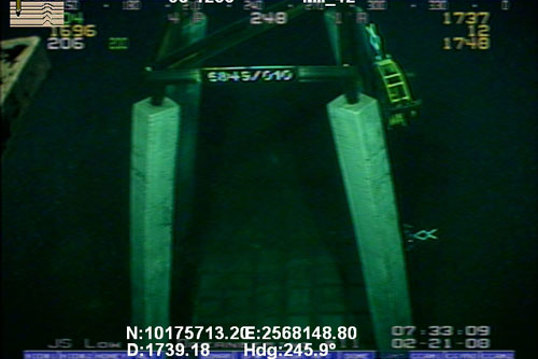

• Various standard and customized RetroClamps™ for electrical attachment.

Installation time: 3 days

The installation was accomplished utilizing a DP-equipped ROV support vessel equipped with two ROVs. An ROV essentially watches the RetroPod™ craned down to the seabed adjacent to the asset and sets the RetroClamp™ onto the target member or pipeline. Electrical continuity and CP measurements were monitored using Deepwater’s Polatrak® Deep-C Meter™ and ROV II™ probe.

The CP design was optimized in a manner that minimized the number of installation sites, but allowed for maximum flexibility with anode array placement. This design feature enabled the installation team to quickly alter the game plan when they encountered a major escarpment at one lay-down site.

The innovative RetroClamp™ system allows the anode array to be clamped and electrically connected to a member of any shape or size, completing the circuit necessary for the cathodic protection system to begin polarizing the structure or pipeline. The RetroClamp™ can be installed by diver or ROV (ROVs in this case).